Latest news

KiVi M3 tonearm

Soulines KiVi M3 tonearm is based on the "mass distribution" principle respect and understanding, which resulted in the unique design of the bearing yoke and arm tube, becoming a one piece element. Following that principle, required also a specifically designed counterweight assembly, as well as a captive uni-pivot bearing, or a "false" uni-pivot. Combination of all these elements resulted in the tonearm with the impeccable tracking abilities, life-like dynamic response and neutral sound, allowing cartridge to show its virtues.

Captive uni-pivot bearing consists of three hardened stainless steel balls and a precisely machined stainless steel pivot. The pivot point is centered between the balls which are in turn held captive by the Derlin cup. This bearing may look as a "classic" uni-pivot, but in fact it is a more sophisticated design, eliminating the unwanted "skating" of a "classic" uni-pivot bearing. In operation this bearing behaves and "feels" more like "rigid" bearing (gimballed) design tone arms, preferred by the majority of end users, due to easier cueing.

Tapered arm tube (wand) and bearing yoke are designed as a one piece component and machined from a solid Derlin (POM-engineering plastic) block to the highest accuracy and precisely drilled all the way through, afterwards. This is an expensive and complex manufacturing process involving many machining operations, but in turn produces an almost ideally shaped arm tube and in this case a bearing yoke as well. That shape without joints is very stiff, far more so than a standard arm tube and also as the taper extent to the thickness of the arm tube walls as well, with the walls being far thicker near the pivot, it effectively reduces standing waves, spreading them in a way that a parallel sided arm tube can not, and also channels away sound-damaging resonances further from the head shell/cartridge, where they have the most negative impact on the sound. Being a non-resonant material, Derlin (POM) also contributes to the more natural sound, without the ringing/rattling and other disturbing side effects that might occur when the arm tube is made from aluminum, stainless steel and other similar materials.

Derlin arm tube with the upper bearing yoke part also forms the bearing carrier. Mass loaded lower part of the bearing yoke which is aluminum made carries the counterweight stub and the side stainless steel stabilizers and it is rigidly bolted to the Derlin arm tube and the upper bearing yoke part.

Such assembly balances (and stabilizes) masses around the arm in such a way that when the cartridge tries to twist the arm at music frequencies the inertia of the arm alone holds it steady and also contribute to the efficient damping of the resonances which will inevitably reach the pivot bearing end of the arm tube, pointing them out of the Derlin arm tube with the upper bearing yoke part to the mass loaded lower part of the bearing yoke, stainless steel stabilizers and counterweight assembly and not reflecting them back towards the head shell/cartridge.

Further, such arrangement places the center of mass of the moving arm parts just below the pivot point and approximately into the same horizontal plane with the LP record, thus allowing almost perfect LP record grooves tracking, which in turn results in excellent dynamic response and neutral sound.

Being already balanced by its specific design, the KiVi M3 tonearm allows an elegant counterweight and VTF (vertical tracking force) adjustment solution. In order to achieve the required VTF (vertical tracking force) for the wide range of cartridges, from the light (5g) to the heavy ones (up to 15g), the KiVi M3 tonearm is supplied with 4 different stainless steel counterweights which are used in the pairs-combinations. Counterweights are of the same diameter, but different thickness (weight) and fixing the counterweights pair in the desired position (required VTF) is gained by tightening-rotating them towards each other; along with simplicity in use, it also allows precise setting of the VTF up to tenths of a gram.

Central arm pillar is precisely machined from the stainless steel and the phono 5-pin output socket is located at the bottom of it, when the tonearm is acquired separately.

When the tonearm is included with Soulines turntable models, instead of 5-pin output socket the quality phono interconnect cable is permanently attached (soldered) at the bottom of the central arm pillar.

Arm height or VTA (vertical tracking angle) is adjusted by vertical movement of the central arm pillar in the aluminum arm base. Locking the tonearm at the desired height is done by two M4 grub screws located at the vertical collar of the arm base.

The head-shell is machined from aluminum alloy, sand-blasted and powder-coated in order to damp as much as possible the sound damaging resonances transmitted from the cartridge body to the head shell. It is rigidly bolted to the arm tube aluminum insert, in a way where the semicircular upper part of the arm tube wall is clamped between the aluminum insert and head shell. Along with clamping the aluminum insert also serves as a grounding post, effectively grabbing RF and EMI interference occurring close to the cartridge and passing them through the grounding wire all the way to the phono pre-amp chassis.

Cartridge Azimuth is adjusted by the rotation of the Azimuth adjustable counterweight, located at the back of the bearing yoke; Azimuth counterweight's correct position is secured by its M4 grub screw.

The anti-skate thread is attached exactly in the horizontal plane where the pivot tip is in contact with the bearing balls, meaning that it pulls only in that plane, thus not trying to twist the arm as it pulls.

Further, the tonearm wires, which usually represent a problem, as they inevitably offer resistance to the arm movement, because they bent as the arm move, are assembled in a way to enter the central arm pillar below the pivot point and as close to it as possible, so that the effect is minimized.

Specifications:

- pivot to spindle distance: 222-224mm (223mm ideally)

- effective length: 240mm

- effective mass: >15

- VTA adjustment: yes

- quality digital scale for the cartridge VTF measurements is included, measuring the cartridge VTF at the "LP record" level (plane)

- delivered without interconnect cable

Please check availability and retail price with your local Soulines distributor/dealer.

tt9

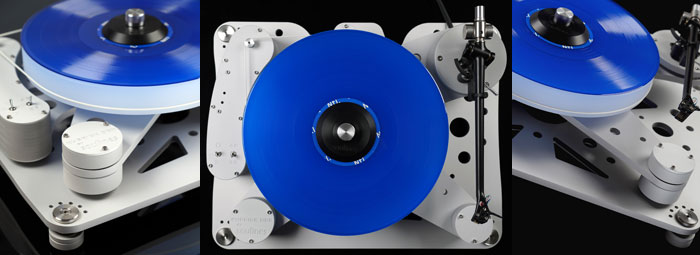

Our new turntable model, the tt9 is designed upon advanced solutions for our top models, the tt42 and the Kubrick DCX. Differently shaped elements, precisely machined and made from the different materials like Cast Acrylic, Derlin (POM-engineering plastic) and aluminum, together form a light, yet highly rigid assembly.

The solid and light construction of the turntable assembly has an important feature of preventing the sound-damaging resonance energy to be stored in the assembly itself; without the excessive mass where the resonances can be stored, they are pretty much channeled out from the assembly itself. The dimensions and shape of the plinth and sub-plinth elements (including the holes arrangements in the elements), were optimized employing Golden Ratio and Fibonacci sequence, thus gaining uniform vibration damping and the reduction of the Moment of inertia in all three planes (along all three axes) to the center of the mass.

Further, tt9 continues our tradition of designing compact high quality turntables which can be considered as an affordable high-end by their performance, but at the same time being extremely user friendly. Set-up of the tt9 is intuitive and straightforward, and does not require any special tools and/or an extensive technical experience.

Main bearing is of an inverted type with stainless steel top outer cup, brass spindle sleeve and stainless steel spindle, all machined to the highest accuracy and employs Derlin thrust plate. Sub-platter is precisely machined from Derlin (POM-engineering plastic) and it is rigidly secured to the main bearing.

The platter, 30mm thick and weighing 2.5kg is precisely machined from the cast Acrylic and together with the advanced main bearing ensures smooth rotation and rumble and noise free performance. It has a 1.0mm deep recess carved on the top for the LP record's paper label, thus when LP record is placed on it, it will lay flat. If you are afraid that records will slip when placed straight onto the Acrylic platter, please use the record clamp included with your tt9, the tt Clamp to firmly clamp/press the LP record onto the platter for the superior sound.

Advanced main bearing and solid aluminum arm-board are mounted directly onto the aluminum made sub-plinth which is in turn 3-point coupled (by means of rubber-cork washers of different thickness and diameters) to the main plinth made of cast Acrylic and Derlin (POM) in order to maximize the performance and minimize acoustic break through. The motor assembly machined from Derlin (POM) is rigidly mounted onto the main plinth.

The drive system is built around the same high quality DC motor used in our advanced turntable models; It's electronically controlled, providing an easy operation and fine speed adjustment feature for both speeds (if required). Speed changing and start/stop functions are simple to operate, just toggle (flip) the on/off and 33/45 toggle switches.

The turntable is supported by three adjustable cones machined from Derlin (POM) to allow easy leveling and optimum coupling to the surface that it sits on. Supporting cones are coupled to the main plinth by means of rubber-cork washers of different thickness and diameters, providing better vibration transmitting control.

High quality Soulines KiVi M3 tonearm is included (pre-mounted) with the tt9 turntable, and with the addition of the quality cartridge it will form an excellent vinyl LP's replaying system.

The tt9 turntable is supplied with:

- dust cover, the SA Cover, an Acrylic (Plexiglass) made dust cover

- record clamp, the tt Clamp

- cartridge protractor alignment tool precisely printed on 300gr paper including Baerwald, Loefgren and Stevenson protractors

- dust cover, the SA Cover, an Acrylic (Plexiglass) made dust cover

- record clamp, the tt Clamp

- cartridge protractor alignment tool precisely printed on 300gr paper including Baerwald, Loefgren and Stevenson protractors

Dimensions:

- over all dimensions: 425x355x145mm

- package box dimensions: 510x410x310mm

- Weight: Net - 10.00kg; Total - 12.00kg

- over all dimensions: 425x355x145mm

- package box dimensions: 510x410x310mm

- Weight: Net - 10.00kg; Total - 12.00kg

Please check availability and retail price with your local Soulines distributor/dealer.

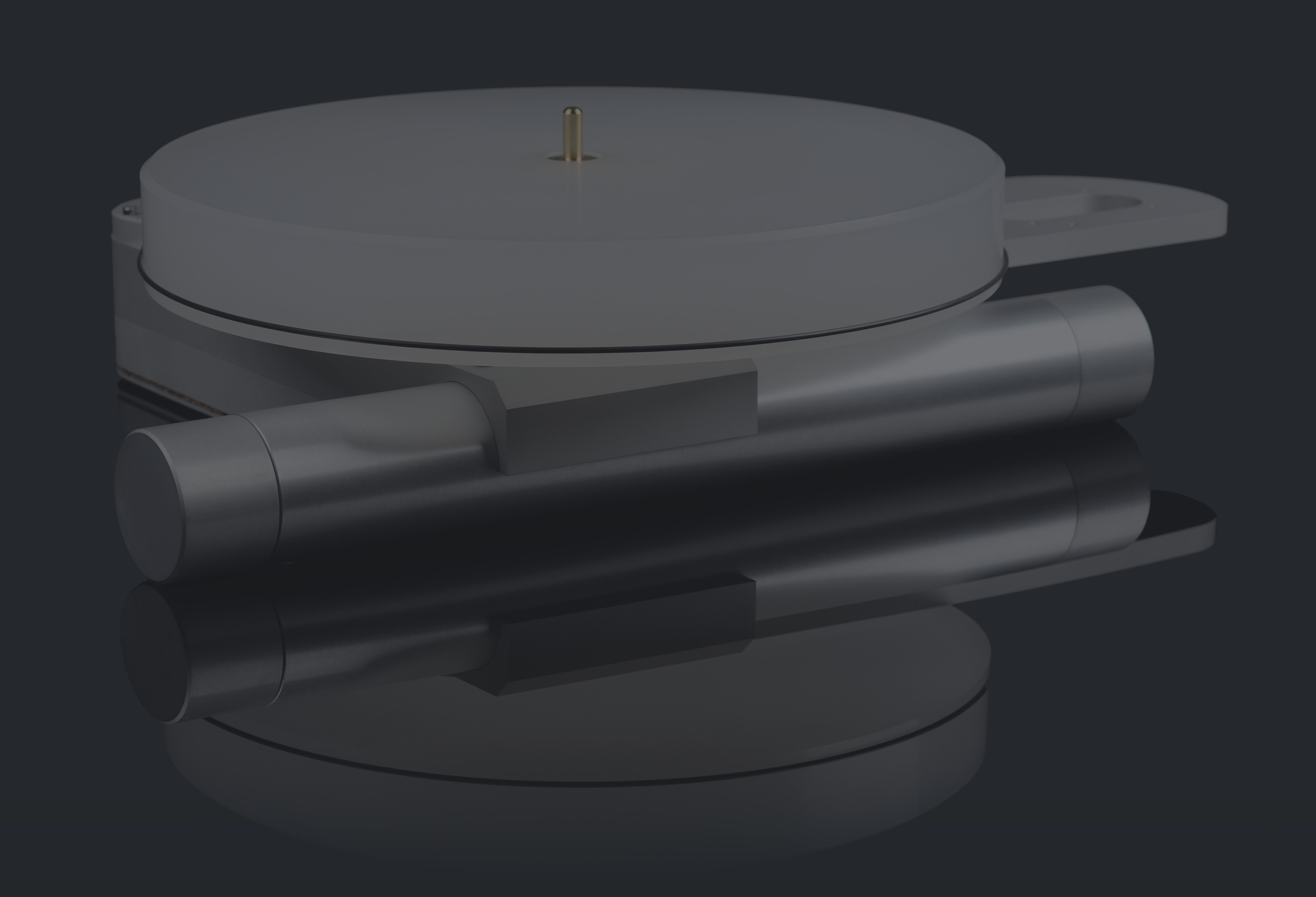

bbs feet

The bbs feet, designed with ball bearing swing mechanisms, serve as resonance-damping devices aimed at mitigating sound interference. They are intended for use with a wide array of audio equipment, including turntables, CD/DVD transports/players, DACs, audio streamers and servers, phono and line tube/solid-state preamps, as well as integrated and power amplifiers and speakers, within specified weight limits.

These feet operate based on Newton's Third Law of Action-Reaction, where sound-damaging resonances dissipate through continuous micro-movements and counter-movements of the moveable bbs foot components. Thus, connection between the bbs feet and the audio component (and/or its chassis) must be a solid one, allowing the vibrations originating from the audio equipment itself to pass to the bbs feet in the fastest manner.

The bbs feet incorporate two rows of polished and hardened stainless steel balls, varying in diameters, housed within independent POM and acrylic discs. Ball bearing balls support two stainless steel plates-discs that can be independently move in relation to one another, the audio device mounted on the upper stainless steel disc, and the aluminum base of the bbs foot positioned on the audio shelf/rack. All mobile components are securely enclosed within a two-part aluminum cup, with the aluminum base further isolated from the shelf/rack using rubber-cork washers. For durability and hardness, the aluminum cup parts are anodized.

The bbs feet incorporate two rows of polished and hardened stainless steel balls, varying in diameters, housed within independent POM and acrylic discs. Ball bearing balls support two stainless steel plates-discs that can be independently move in relation to one another, the audio device mounted on the upper stainless steel disc, and the aluminum base of the bbs foot positioned on the audio shelf/rack. All mobile components are securely enclosed within a two-part aluminum cup, with the aluminum base further isolated from the shelf/rack using rubber-cork washers. For durability and hardness, the aluminum cup parts are anodized.

The bbs feet feature a distinctive design that adheres to the Golden Ratio for the dimensions of the bbs foot components. Along with the use of high-quality stainless steel ball bearings and precision CNC machining, these feet effectively eliminate sound-resonance issues originating from the audio equipment itself. Simultaneously, they prevent external sound interferences from the audio shelf/rack.

Utilizing bbs feet provides numerous advantages for sound reproduction, including a more dynamic and natural sound with an expanded sound stage in terms of depth, width, and height. They also enhance the clarity of audio details and the intelligibility of human voices, facilitating a more emotional and enjoyable listening experience when enjoying favorite LP records, CDs, or digital sound files.

Each bbs foot can accommodate a maximum weight of up to 15kg, with the recommended load for optimal performance falling within the 1-10kg range.

The bbs feet are available in sets of 3 or 4 pieces, so the maximum loads are:

45kg - 3 pieces set

60kg - 4 pieces set

Recommended loads for the optimal performance are:

1 - 30kg - 3 pieces set

1 - 40kg - 4 pieces set

The bbs feet are available in sets of 3 or 4 pieces, so the maximum loads are:

45kg - 3 pieces set

60kg - 4 pieces set

Recommended loads for the optimal performance are:

1 - 30kg - 3 pieces set

1 - 40kg - 4 pieces set

Specifications:

- diameter - 68mm, height - 32mm;

Shipping weight - 3 pcs set - 1.160kg

Shipping weight - 4 pcs set - 1.420kg

- diameter - 68mm, height - 32mm;

Shipping weight - 3 pcs set - 1.160kg

Shipping weight - 4 pcs set - 1.420kg

The bbs feet can be placed under the existing feet of your equipment or may also be used directly under the equipment's chassis, by-passing the stock feet. Please note that bbs feet should not be ever placed under any kind of the equipment's feet made of rubber, cork, rubber-cork, elastic polymers and similar damping materials, as those kind of "soft" and elastic feet materials act as a barrier for the vibrations originating from the audio equipment itself, namely the vibrations can't get pass through such a kind of material, thus the bbs feet won't work. Feel free to experiment with the placement positions of the bbs feet under your equipment in order to achieve the best sound performance.

Please check availability and retail price with your local Soulines distributor/dealer.

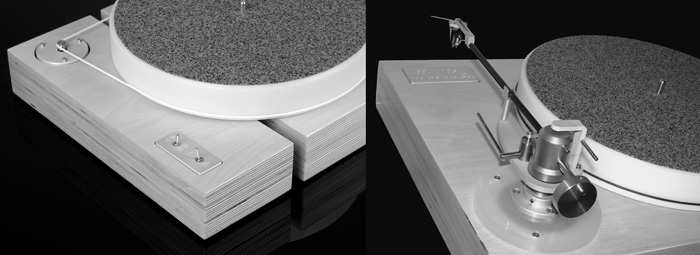

tt42

The number 42 usually has no meaning other than mathematical, but when placed in the context of the science fiction novel "Hitchhiker's Guide to the Galaxy" by the famous Douglas Adams, where the number 42 is the answer to the "question about the meaning of life, the universe, and everything", the number 42 also gains a serious philosophical meaning. As no one can tell which is the best turntable in the world, because we still don't know what that turntable should be like, what characteristics it should have, etc. namely we don't know how to correctly formulate the question what's the best turntable in the world, it is also impossible to correctly formulate the question about the meaning of life, the universe and everything, and get some meaningful answer. So, the number 42 is the perfect answer to that question, as long as the question is formulated in that way. Until we determine what's the best turntable in the world should be, the tt42 could be the answer.

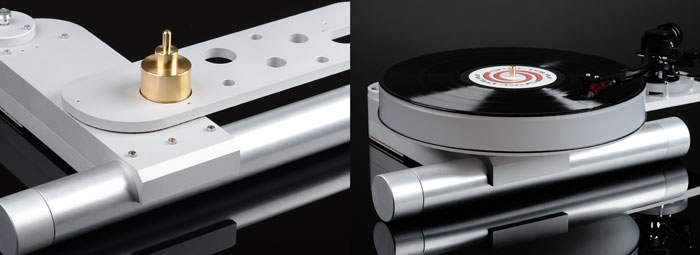

Design of the tt42 was done using 3D-modeling software and employing Golden Ratio and Fibonacci sequence, in order to attain a fully mechanically balanced system. Thus, the center of mass of the turntable is placed onto the vertical axis of rotation of the main bearing shaft/platter, reducing Moment of inertia to the very center of the mass. To gain uniform vibration damping across the whole frequency spectrum, different materials like acrylic, aluminum and stainless steel, had been chosen for the plinth and sub-plinth components according to their specific mechanical characteristics. All the components are precisely CNC machined and hand finished to the highest standards.

Acrylic made main plinth, massive aluminum sub-plinth and motor assembly are 3-point or 4-point coupled over differently sized rubber-cork washers for damping, thus gaining maximum control of the vibrations transfer through the complex plinth/sub-plinth/motor-pod assembly. Both arm-pods and main bearing assembly are tightly mounted directly onto the massive CNC machined aluminum sub-plinth, which is in turn 3-point coupled to the main Acrylic plinth over the differently sized rubber-cork washers used for damping.

Main bearing assembly is of inverted type, precisely CNC machined and finished to the tightest of tolerances. Bearing top hub is machined from solid stainless steel and comprises brass sleeve insert and Derlin thrust pad. A polished stainless steel shaft holds captive hardened steel ball bearing, at the top, ensuring that the ball is housed absolutely central to the shaft. The platter, 60mm thick and weighing 5.4kg, is machined from laminated cast Acrylic to a very high accuracy. The use of mat is completely up to the user preferences, thankfully to the 1.0mm deep recess carved into the top plane of the platter in the middle (for the record paper label) and to the fact that Acrylic proved itself as a great turntable mat "material". Complete main bearing assembly and platter are individually manufactured to fit each other specifically, rather than manufacturing in batches.

Drive mechanism utilizes a powerful, high torque brush less DC motor and with an integrated speed control electronic driver, while the motor controller is a true analog device, providing constant speed and uniform rotation, which in turn ensures perfect natural dynamics, timbre, timing and musicality of every record played. Fine speed adjustment feature is provided for both speeds 33.33rpm and 45rpm.

The turntable is supported by three adjustable massive cone feet CNC machined from solid stainless steel to allow leveling and provide optimum coupling to the surface that it sits on. Cone feet are coupled to the particular aluminum pods over the rubber-cork washers of different diameters, while in turn the aluminum pods are 3-point coupled to the main Acrylic plinth again over differently sized rubber-cork washers for damping. Thus, structural vibration break through (from the environment through shelf/rack/stand) is minimized and can be neglected.

Two identical arm-pods consist of several parts: the upper part, the lower part and the arm-board (SME x 2, Jelco/Linn/Ortofon, Rega/Origin Live/Audio Note/etc. mounting standard), all CNC machined from aluminum and 3 sets (of 4) of spacers of different heights (15, 20, 25 mm) made of stainless steel . The upper and lower part are tightly connected with six M4 bolts and can slide over each other, so the required change of geometry for different tone-arms lengths, 9 or 12 inches, is quite easy, unscrewing the M4 bolts, sliding the upper part to the appropriate position and tightening the bolts again. Right arm-pod with the SME arm-board is factory fitted, while mounting of the second (left) arm-pod (comes partially assembled) is quite easy using six M4 bolts (supplied). Custom arm-boards are available through us, by request and upon submitting necessary technical drawings of the particular tone arm specific mount.

The turntable is supported by three small silicone rubber pucks.

Included in the package:

- three different (user) exchangeable aluminum made arm-boards:

- two SME arm-boards - tone-arm pivot to spindle distance from 199-241mm (9”) and 275-317mm (12”)

- Jelco arm-board - tone-arm pivot to spindle distance 214mm (9”) and 290mm (12”)

- Rega/Origin Live arm-board - tone-arm pivot to spindle distance 222mm

- partially assembled second arm-pod

- 3 sets (of 4) of stainless steel spacers of different heights 15, 20 and 25mm

- high-performance rubber-cork mat

- cartridge protractor alignment tool including Baerwald, Loefgren and Stevenson protractors

Please check availability and retail price with your local Soulines distributor/dealer

the loop

The Loop phono pre-amplifier is based around pair of NOS ECF80 tubes, employed in the RIAA equalization and MM gain stage, utilizing unique passive RIAA curve equalization, thus providing very neutral sound along with the natural tonal colors of the voices and instruments. The Loop is essentially hand made product, utilizing only components which are carefully selected and matched.

MC step up gain section is done with J-fets in SMD technology, providing a high MC gain suitable for wide range of MC cartridges, along with MC input impedance (MC load) set-up feature for three most common loads, 50ohm, 100ohm and 200ohm, select-able by micro-switches at the back panel of the unit.

NOS ECF80 tubes and all the parts and elements are rigorously hand selected and matched, after extensive measuring and listening tests, in order to provide a great performance. ECF80 tube sets should last for more than 5000 hours, and matched pairs of NOS ECF80 tube sets are available as spare parts.

When designing the all aluminum case-enclosure, we employed our extensive experience from the turntable design and construction, utilizing 10mm thick aluminum panels, strategically damped and solid aluminum cones-feet damped by rubber-cork washers, doing everything in order to provide a stable mechanical base for the electronics and tubes to work.

Along with the standard 230VAC power supply version, 115VAC power supply version is available as well, differing from the standard version only by the different values of mains transformer and fuse used.

Features and characteristics:

- Hybrid tube design with ECF80 tubes

- MM & MC capability

- MM & MC capability

- RIAA accuracy - 0,5dB/20Hz-20kHz

- MM gain - 38dB

- MC gain - 64dB

- Input impedance MM - 47kohm

- Input impedance MC - 50,100,200 ohm

- Output impedance - 3kohm (load over 20kohm)

- Power supply - 230VAC 50-60Hz or 115VAC 50-60Hz

- dimensions WxDxH - 310x280x125mm

- total weight - 6.95kg

Please check availability and retail price with your local Soulines distributor/dealer