We find and approach turntable design/building similarly to the music instruments design/building.

Music instrument should provide a good base (tool) for an artist to successfully present a music piece, likewise turntable with the tone-arm, should provide good base for the needle-cartridge system to successfully transduce mechanical energy generated while tracking the record grooves to the electrical energy, i.e. sound. Thus, like with music instruments, successful turntable design is based on the advanced vibration control, and beside required quality of the instrument/turntable, the final result also depends on artist virtuosity, or in our case on quality and characteristics of tone-arm and needle-cartridge.

In Soulines, we consider that all turntable components/parts and interaction between them are equally important, thus we always balance a number of “good compromises”.

There is no point of taking one of the component(s) to the extreme, like for example mass of the platter or a chassis (plinth). All the parts should "work" together in order to achieve good performance.We do not believe in extravagant (complicated) engineering and materials. Simple engineering and clever material selection usually gives the best results.Our production is not cost-optimized manufacturing processes.

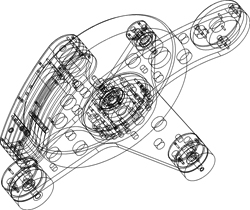

Our turntables are essentially handmade, supported by high technology of CAD and 3D-SW design software, and CNC manufacturing.

Three main principles of our turntable design and manufacturing are:

- turntable should reproduce music as faithfully as possible

- it has to be easy to use and set-up

- it must look beautiful

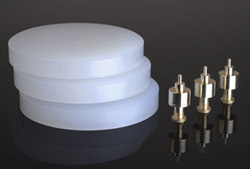

Different materials used in our turntables are carefully chosen according to their acoustic and mechanical properties. Critical turntable parts like platter, main bearing and spindle are individually manufactured to fit each other specifically, rather than manufacturing in batches. All aluminum parts are precisely CNC machined.

Three main principles of our turntable design and manufacturing are:

- turntable should reproduce music as faithfully as possible

- it has to be easy to use and set-up

- it must look beautiful

Different materials used in our turntables are carefully chosen according to their acoustic and mechanical properties. Critical turntable parts like platter, main bearing and spindle are individually manufactured to fit each other specifically, rather than manufacturing in batches. All aluminum parts are precisely CNC machined.

For damping, we use rubber-cork sheets of different thickness/shape, or system of rigidly coupled few different materials (layers), thus reducing surplus resonance's of the said component(s) to minimum.

Parts and components are thoroughly examined before final assembly, hand-finished and assembled to very high accuracy ensuring an excellent performance.

Finished units are rigorously tested before packing and shipping.

Parts and components are thoroughly examined before final assembly, hand-finished and assembled to very high accuracy ensuring an excellent performance.

Finished units are rigorously tested before packing and shipping.